Are they real? Yes!

Lab created diamonds have the exact same chemical structure as natural diamonds. The only difference between the two is simply how they were created. Natural diamonds are created in the Earth’s mantle and lab created diamonds are man-made in laboratories.

Lab created diamonds have an identical appearance to natural diamonds. Even trained gemologists find it nearly impossible to tell the difference between them. Special machines are usually required to identify whether a diamond is man-made, or was mined from the Earth.

If They’re Real, Why Are They More Cost Effective?

The price point of a lab created diamond is not a reflection on quality – they are exactly the same as natural diamonds. It is, instead, the difference in the process of mining diamonds vs. creating diamonds in a lab.

Natural diamonds are mined and have a long journey along a supply chain. By the time a diamond reaches a retailer, miners have dug it out of the ground, it has passed through distributors, it has been in the hands of cutters and polishers, and then jewelry manufacturers.

Lab created diamonds, on the other hand, have a more streamlined process of getting to consumers that makes them less expensive to produce than mined diamonds. That savings is passed on to you.

Again, both lab created and mined diamonds are considered exactly the same. The Federal Trade Commission (FTC) made that determination in 2018 when it revised its definitions for diamonds once laboratory created diamonds took root in the marketplace. They issued a ruling at that time stating that “lab-created products that have essentially the same optical, physical, and chemical properties as mined diamonds are also diamonds.”

What’s Their Environmental Footprint?

While lab created diamonds require a high amount of energy to produce, they are considered to have less of a direct impact on the environment than mining.

While lab created diamonds require a high amount of energy to produce, they are considered to have less of a direct impact on the environment than mining.

And while diamond mining companies do take measures to minimize their effect on the environment, any time you dig a natural resource out of the ground the area will be impacted.

Lab created diamonds, on the other hand, are created in factories and while the process entails a fair amount of energy to produce diamonds, the factories are considered less impactful on the environment.

Learn more about Anjolee’s Green Manufacturing

How is a Lab Created Diamond Made?

There are two processes used to create diamonds in a lab – High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both diamond-making processes begin with a diamond seed, which is a small and flat wafer-like fragment similar in size and shape to a silicon chip.

The CVD Method

The Chemical Vapor Deposition (CVD) method of creating diamonds has gained the most worldwide interest from researchers and diamond industry experts. CVD is a simpler process and is less costly than HPHT because it does not require such intense pressure and heat.

Here’s how it works:

- First, a diamond seed is smoothed and polished, then placed inside a vacuum chamber containing a hydrocarbon gas mixture. A dozen or so seeds can be placed inside the chamber at a time.

- Inside the chamber, the gases (which include a carbon source such as methane and hydrogen) are heated to create what is called a plasma ball.

- The heat is increased inside the chamber, which causes the gases in the plasma ball to attach and crystallize on top of each diamond seed.

- After a few weeks, the seeds will have grown to approximately 10 times their original size.

- When the process is complete, the rough diamonds are then removed from the chamber. From there, they are cut and polished to perfection.

The CVD method is typically used for creating larger-carat diamonds.

The HPHT Method

High Pressure-High Temperature (HPHT) is the method that General Electric first used in the 1950s, and it is still used today. Producing diamonds using the HPHT method is costly because of the large amount of energy that is required, along with the expense associated with the equipment.

Here’s how it works:

- One of three types of presses (a belt press, cubic press or split-sphere press) is used to apply an intense amount of pressure and high temperature to a diamond seed.

- The pressure and heat are combined with a carbon source to form (or ‘grow’) a diamond.

- Once the process is complete, the resulting stone is cut and polished to prepare it for commercial use.

Typically, the HPHT process is used to create smaller diamonds. It is also well-suited for industrial applications, such as creating diamonds for use in cutting tools.

The History of the Lab Created Diamond

Attempts were first made in the 1800s and early 1900s to create diamonds out of carbon and you can even find an early lab created diamond (made in 1926) on display at a museum in Kansas.

By the 1940s researchers in the United States, Sweden and the Soviet Union were working on methods to create diamonds. They discovered two processes (discussed earlier in this article) that replicated how natural diamonds are created:

- HPHT (High-Pressure High-Temperature)

- CVD (Chemical Vapor Deposition)

The first commercially successful man-made diamond was created in 1954 as part of a project by General Electric and an official announcement was made in early 1955.

General Electric had partnered with two other companies to further develop a diamond-making process and while the diamond they created was not ‘gem-quality’ the project paved the way for future developments. Sweden researchers were also successful in creating diamonds in a lab at that time.

The processes the early researchers discovered were perfected over time and in the late 1980s lab created diamonds became available commercially. Fast forward to today and man-made diamonds are now sold by many jewelers, including Anjolee, as an alternative to mined diamonds.

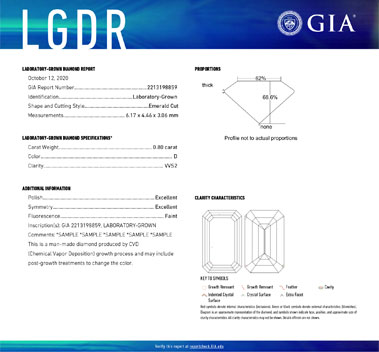

Is Third-Party Certification Available for Lab Created Diamonds?

Yes, Anjolee works closely with accredited gemological laboratories that evaluate both natural and lab grown diamonds, and provide third-party certification.

Gemological Institute of America (GIA)

The GIA specializes in certifying loose diamonds and they certify and provide documentation for lab created diamonds, in addition to natural diamonds.

The GIA performs the same full 4C’s assessment for carat, cut, clarity and color that they do for natural diamonds.

Certifying lab grown diamonds with the GIA is recommended for diamond stud earrings, and the center stones of engagement rings. Certifying diamonds for other types of jewelry, like a tennis bracelet or necklace, however, is usually not cost effective, as the charge is applied per stone certificate.

International Gemological Institute (IGI)

The International Gemological Institute (IGI) certifies completed pieces of diamond jewelry made with either natural or lab created diamonds.

The IGI thoroughly documents the jewelry’s identification according to weight, measurements, shape, cut, finish, proportions, clarity, color, and the quantity of precious stones. Documentation also includes the item’s precious metals (i.e., by weight and content).

An IGI certificate is ideal for finished diamond jewelry such as bracelets, necklaces, earrings and rings.